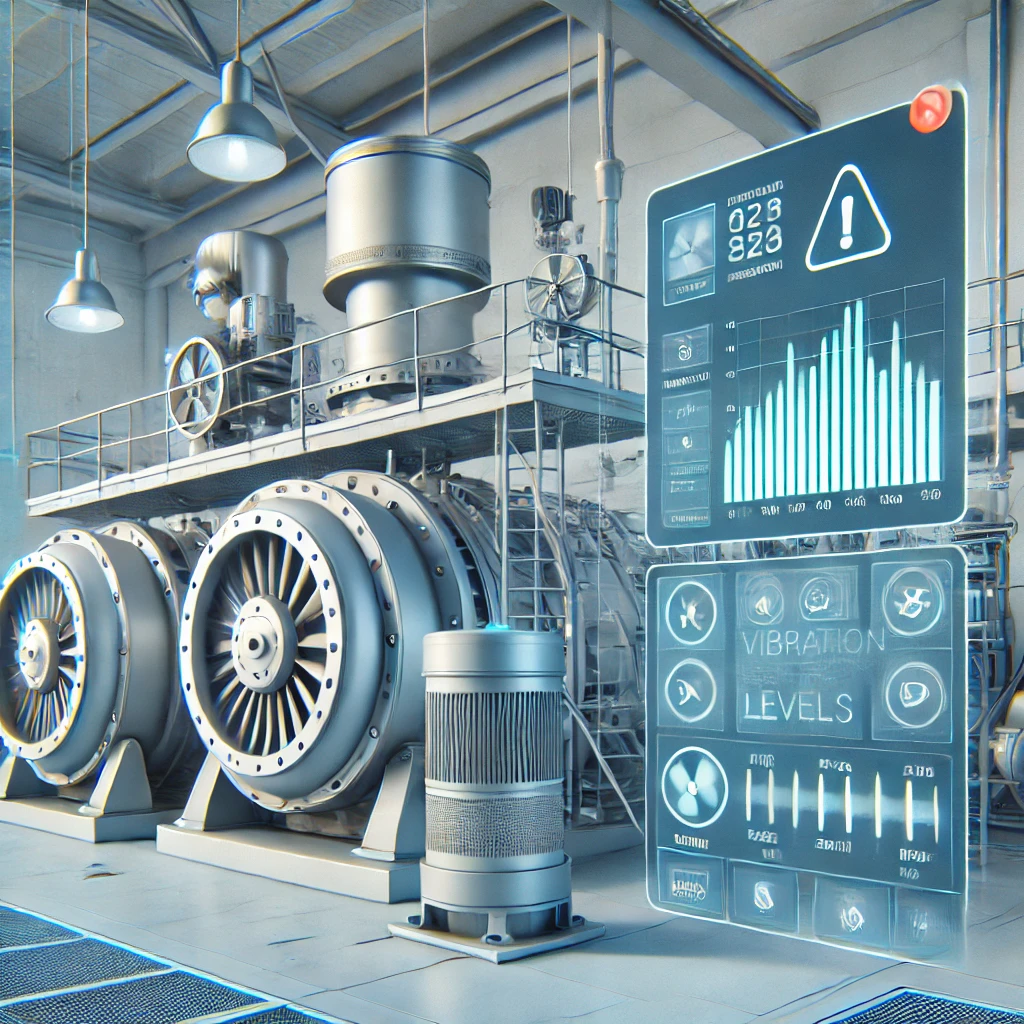

Vibration monitoring system

A vibration monitoring system is essential for ensuring the reliability of equipment and preventing costly failures. By providing real-time data on vibrations, these systems identify anomalies, analyze machinery performance, and support process optimization.

Key Benefits

- Preventive Diagnostics: Early detection of issues reduces downtime and repair costs.

- Enhanced Safety: Minimizes risks of equipment failure and accidents.

- Cost Savings: Optimized maintenance schedules lower operational expenses.

- Prolonged Equipment Lifespan: Timely interventions extend machinery durability.

Features

- Real-time vibration monitoring for high precision.

- Data logging and archiving for thorough analysis.

- Customizable alerts for abnormal parameters.

- Compatibility with industrial protocols like ModBus and PROFIBUS.

Applications

- Industrial Equipment: Monitor pumps, motors, turbines, and other critical machinery.

- Energy Sector: Ensure the stability of generators and transformers.

- Transport Systems: Diagnose issues in moving components and vehicles.

- Production Lines: Maintain consistent operations and detect irregularities.

The INOBALT vibration monitoring system provides a reliable solution for optimizing operations and maintaining equipment. Contact us today to learn more about how we can help you improve efficiency and safety.

English

English  Lietuvių

Lietuvių  Русский

Русский