Process Monitoring in a Brewing Plant

|

|

The customer is one of the world largest brewing companies. This brewing plant is located in Eastern Europe and produces about 600.000 litres of beer for the export markets in USA, Russia, Sweden and Norway. |

Application / Problem:

The customer decided to install a Delphin LogMessage data logging system to monitor the consumption of:

-

electrical energy

-

CO2 for beer carbonizing process

-

steam flows

-

sewage flows

-

fresh water

The objective is to install an easy to configure real time monitoring system with reporting capabilities to monitor the consumption of the parameters mentioned above.

Proposal / Solution / Hardware:

|

|

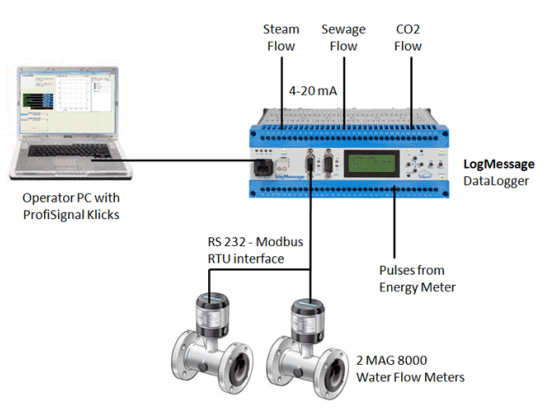

For this installation a LogMessage 200 with 10 universal analog inputs and 11 digital and counter inputs was installed in a control cabinet of the production plant. |

The analog inputs are interfaced with different steam, CO2 and sewage flow meters via 4-20 mA signals. The interface of the 2 water flow meters from Siemens MAG 8000 was realised through the Modbus RTU interface. The Modbus registers where easily created on the 2 serial COM ports of the LogMessage device. The customer is also using the internal calculation channels to calculate consumption indicators. For example the integrator channel is used to totalize the electrical energy and CO2 consumption of the brewing process. The functional design is shown below.

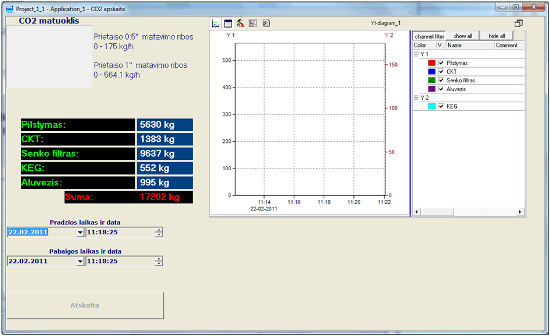

The process supervisor has a PC with a ProfiSignal Klicks software application to monitor the live data of the process. The mimic interface was easily developed with the ProfiSignal software and is shown below.

Benefits:

The advantages of the LogMessage installation are the following:

-

The LogMessage with universal analog and digital inputs can easily record all analog 4-20 mA signals and also the digital inputs from the energy meter with pulse output.

-

The LogMessage devices support many serial interfaces (RS232, 485, 422) and the MAG 8000 flow meters could be easily interfaced via Modbus RTU protocol.

-

The internal calculation channels for alarm monitoring and totalizes (integrator channel) give the operator live readings of key consumption indicators.

-

The internal logger memory with 1 GB capacity is storing the process data for backup functions. The live data is also archived in the DataService Configurator online data base.

-

The ProfiSignal Klicks software also enable the operator to generate different reports and statistics of the process.

For more information please see: LogMessage >>

English

English  Lietuvių

Lietuvių  Русский

Русский