Data Logging on Natural Gas Dehydration Plants with Remote UMTS Access

|

|

This customer is a state owned Oil and Gas company located in Eastern Europe. The company is developing natural gas in remote located gas fields. The gas which is coming out of the wellhead is processed in dehydration plant to extract the water of the gas before it is going through the compressor station and pumped though the pipelines. |

Application / Problem:

The dehydration plant is located in a remote location and the customer needed a standalone data acquisition and logging system to record production and process data of the plant and to have also remote access to the recorded data.

Proposal / Solution / Hardware:

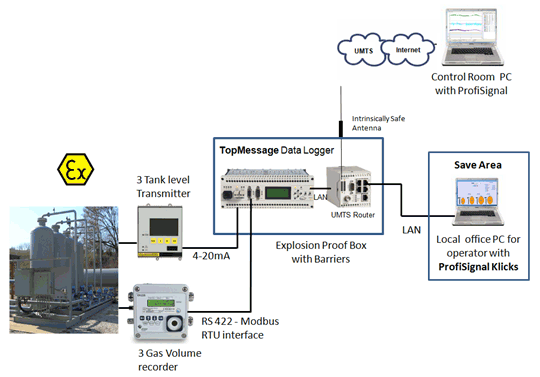

The customer decided to implement on two dehydration plants Delphin data logging systems. In the plant a TopMessage data logger with 1 GB internal memory and one ADVT module with 15 analog inputs and one IOIT module with 24 digital inputs for status monitoring were installed. The data logger is interface via Ethernet (LAN) to a MoRoS UMTS router to provide remote access functions. The complete system is fitted to an explosion proof box with EX barriers in the hazardous area of the plant. The TopMessage data logger is interfaced to three tank level transmitters with analog output signal (4-20mA) and to 3 gas volume conversion devices from VEGA through a Modbus RTU interface.

The functional architecture of application:

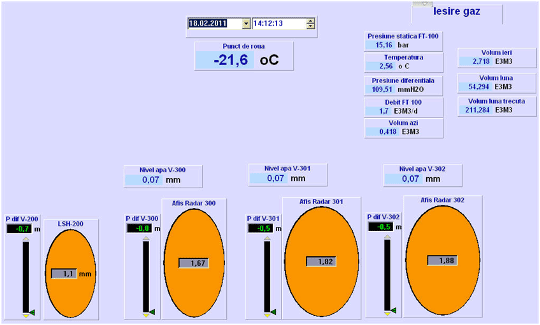

The local plant operator is based in the save area and has a local monitoring PC with a ProfiSignal Klicks installation. The operator has the following mimic panel to monitor the performance of the dehydration plant.

With the UMTS router the control room operator at head office has at any time remote access to the data from the TopMessage data logger and can see live data and download data from the logger memory. The data download can be automated by using the scheduler function of the DataService Configurator. The dehydration plant is covered by an EDGE G2 mobile communication network.

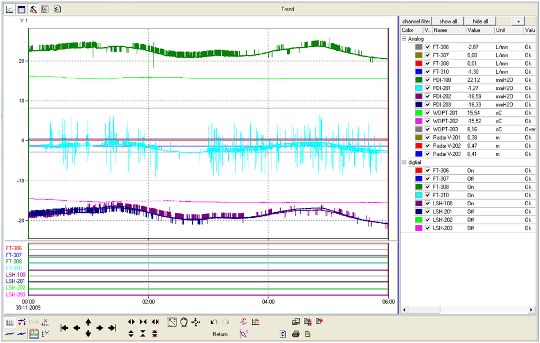

The following diagram shows data from of the dehydration plant.

Benefits:

The TopMessage data logger with UMTS router was the ideal solution for this application as all requirements could be covered:

-

The TopMessage has a small size of (200 x 118 x 90mm) which make the system handy for an installation in the explosion proof box.

-

TopMessage is supporting many serial interface standards so that VEGA Scan EK220 volume conversion units could be interfaced.

-

With the UMTS router remote access could be configured.

-

The UMTS router is also providing networking functions for local PCs and printers.

-

User friendly ProfiSignal Klicks software to develop an operator user interface (mimics) and reporting functions.

For more information please see: TopMessage >>

Have a question?

{rsform 2}

English

English  Lietuvių

Lietuvių  Русский

Русский